Abc Spare Parts Analysis

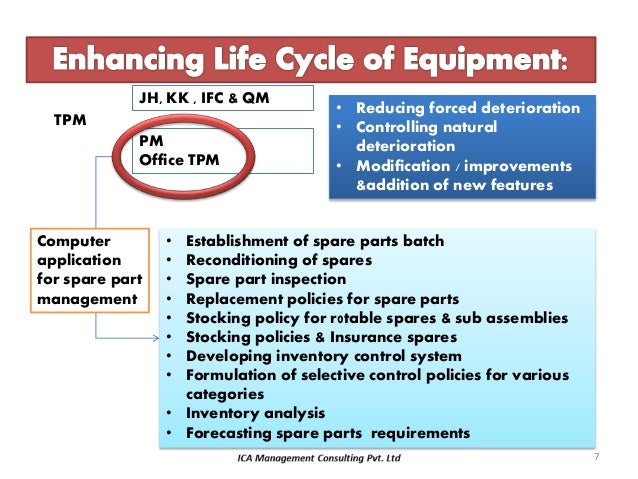

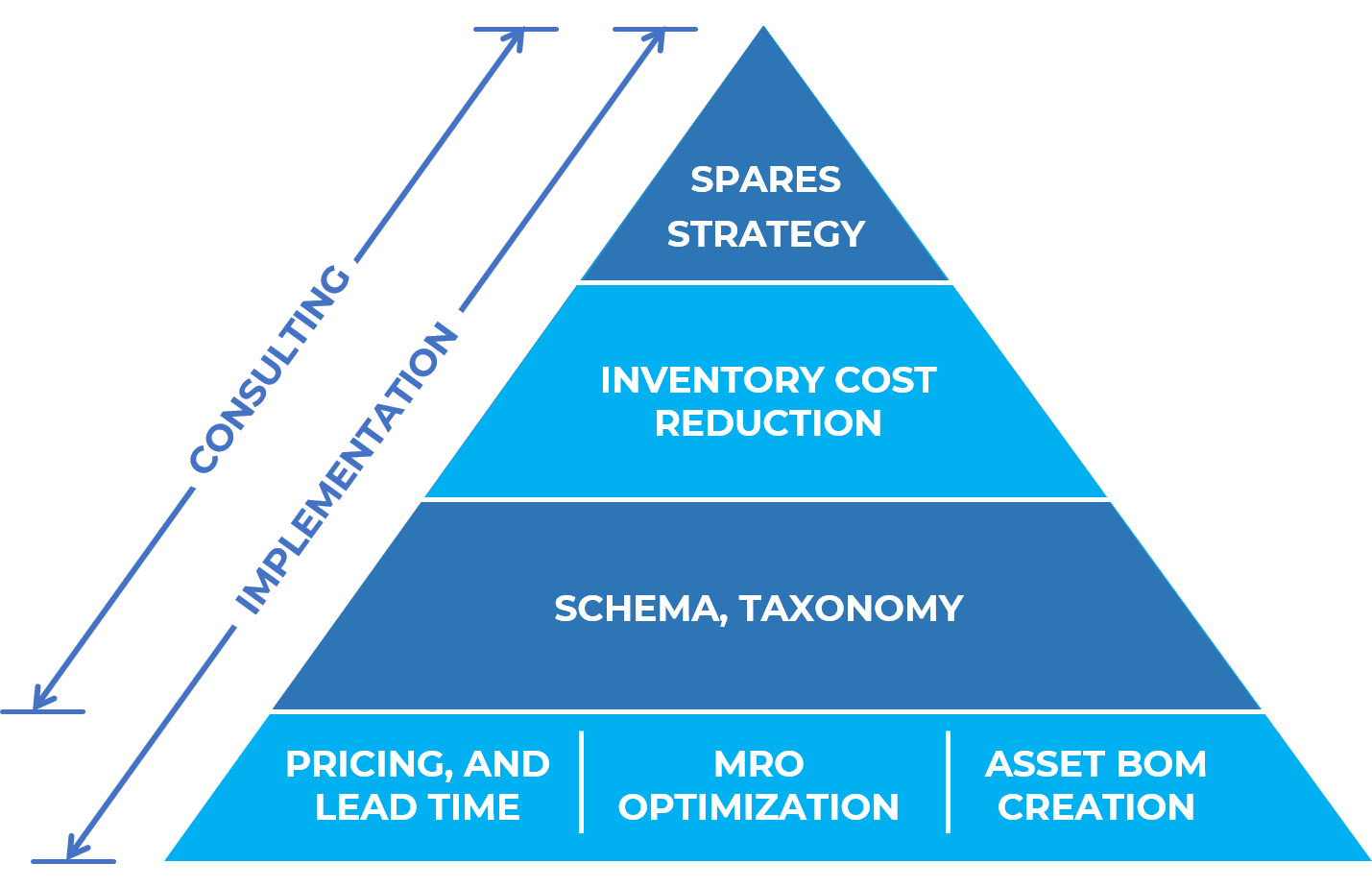

Abc Spare Parts Analysis. On the one hand, advance purchase and storage is connected with bearing inventory costs. Support the optimum maintenance strategy and availability targets and avoid unnecessary costs by optimizing your spares and materials Assessing spare part requirements is important when considering the availability of a system and deciding the optimum maintenance task.

By using original ABC spare parts you can count on reliable parts for maximum usability.

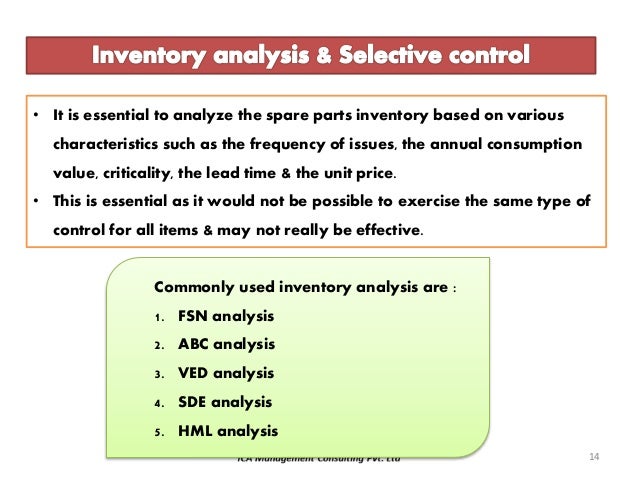

Pareto gained notoriety for saying that most economic productivity comes from only a small part of the economy. common spare parts, fixed maintenance spare parts, easily damaged spare parts, non-fragile spare parts, main spare parts, establishes the hierarchical structure model, and obtains the combined different from the results of the traditional ABC classification method by comparative analysis.

ABC Analysis ABC Method of Inventory Control It has become an indispensable part of a business and the ABC analysis is widely used for unfinished good, manufactured products, spare parts, components, finished items and assembly items. Active spare parts analysis is essential for the optimal definition, identification, procure-ment and supply of spare parts and for inventory and cost A tailored spare parts package is developed for each data center using a method independent from the manufacturer on the basis of a Failure Modes. Two types of analyses are available: stock computations for normal system support, and optimized stock quantities when you face a budget.

0 Response to "Abc Spare Parts Analysis"

Posting Komentar